Tungsten Alloy Block for Extrusion Die

Extrusion die is one of the forming techniques used in material processing, consisting of forcing the work pieces through a die, thereby reducing its cross section and increasing its length.Tungsten alloy block is the popular used part of extrusion die because of its high melting point and corrosion resistace.

Process of Extrusion Die

Extrusion die includes direct and indirect the two main processes. The ingot moves relative to the container wall with direct extrusion, however with indirect, the die moves.

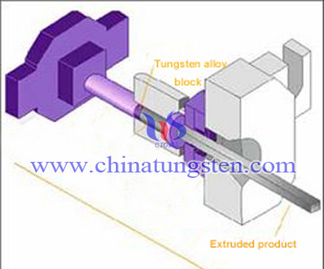

Direct extrusion is the most common extrusion process. The second picture clearly shows the process of derect extruding products.It works by placing the billet in a heavy walled container. The billet is pushed through the die by a ram or screw. There is a reusable tungsten alloy block between the ram and the billet to keep them separated.Indirect extrusion, also known as backwards extrusion, the billet and container move together while the die is stationary. The die is held in place by a "stem" which has to be longer than the container length. The maximum length of the extrusion is ultimately dictated by the column strength of the stem. Because the billet moves with the container the frictional forces are eliminated.

The Advantages of Tungsten Alloy Block

why we adopt tungsten alloy block for parts of extrusion die instead of lead or aluminum or other materials' block?Because tungsten alloy has high melting point more than ten times higher than lead, which is important in extrusion die process. Then, tungsten alloy has high Mohs hardness. What is the most important reason is that tungsten alloy is environment friendly, which lead can not reach.

We are striving to provide high quality tungsten alloy block with excellent services and competitive prices. We hope to achieve a win-win situation with our customers.